Custom production

KOVO-HEPNAR s.r.o. offers, in addition to its standard products, custom production of machines and devices, clamps, jigs, tools and molds. The company has its own design office, which drafts suitable solutions for customer requirements. It uses the modern CAD system SolidWorks for the design and 3D visualisation of new machines or devices. SolidCAM is used for programming CNC machines.

What we offer

Milling

We use 3-axis machining for 3D milling of moulds, press tools and complex components.

Turning

We offer fast and precise turning on modern CNC turning machines with driven tools and Y axis.

Laser engraving

We provide marking of parts and engraving of moulds

Flat-surface grinding

We perform flat-surface grinding up to dimensions 600 × 200 mm.

Manufacture of machinery and equipment

KOVO-HEPNAR s.r.o. offers complete production of machines and machinery according to customer requirements.

Electro-chemical polishing of stainless steel

We provide electro-chemical polishing of stainless steel products and weldments

Production technology

CNC vertical machining centre HARTFORD MVP 10 AP

Very precise and highly productive machining centre.

Basic machine parameters:

axis travels:

x = 1050 mm

y = 530 mm

z = 630 mm

table size 1200 mm × 560 mm

spindle centre cooling 20 bar

The centre is equipped with a 4th axis – a rotary table with continuous control, which can work in a vertical or horizontal position.

CNC lathe DOOSAN LYNX220 LYC

Compact and high-precision horizontal lathe with Y axis.

Basic machine parameters:

Max. diameter of a turned flange 300 mm

Max. diameter of a turned bar 65 mm

Number of driven positions in the tool head 12

Laser engraving equipment HXM20 – COMPACT III

Machine with laser source + computer.

Flexible design, standard and 360° changing angles, movable arm and mini scanner with 2 red beams. High speed marking.

Transmits regular impulse doses with a wavelength of 1060 nm and a power of up to 7 kW.

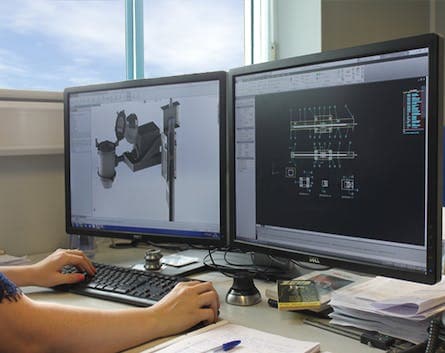

Software equipment

We use SolidCAM for programming CNC machine tools.

We design and draw machines and devices to order

We specialise in measuring instruments, equipment for the food industry and especially moulds for the plastics and rubber industries

We draw in 3D CAD software – SolidWorks

Three reasons for KOVO-HEPNAR s.r.o.

Modern production technology

With its state-of-the-art equipment, KOVO‑HEPNAR s.r.o. can guarantee the production of individual parts, machines and devices with the highest level of accuracy and reliability for strict customer requirements. The range of machines includes HARTFORD, DOOSAN CNC machining centres and a number of other specialised devices and machinery

Hundreds of successful realisations

Machines and equipment manufactured by KOVO‑HEPNAR s.r.o. are supplied to many countries in Europe, Asia, Canada and Australia.